- Home /

- New product tool

New product tool

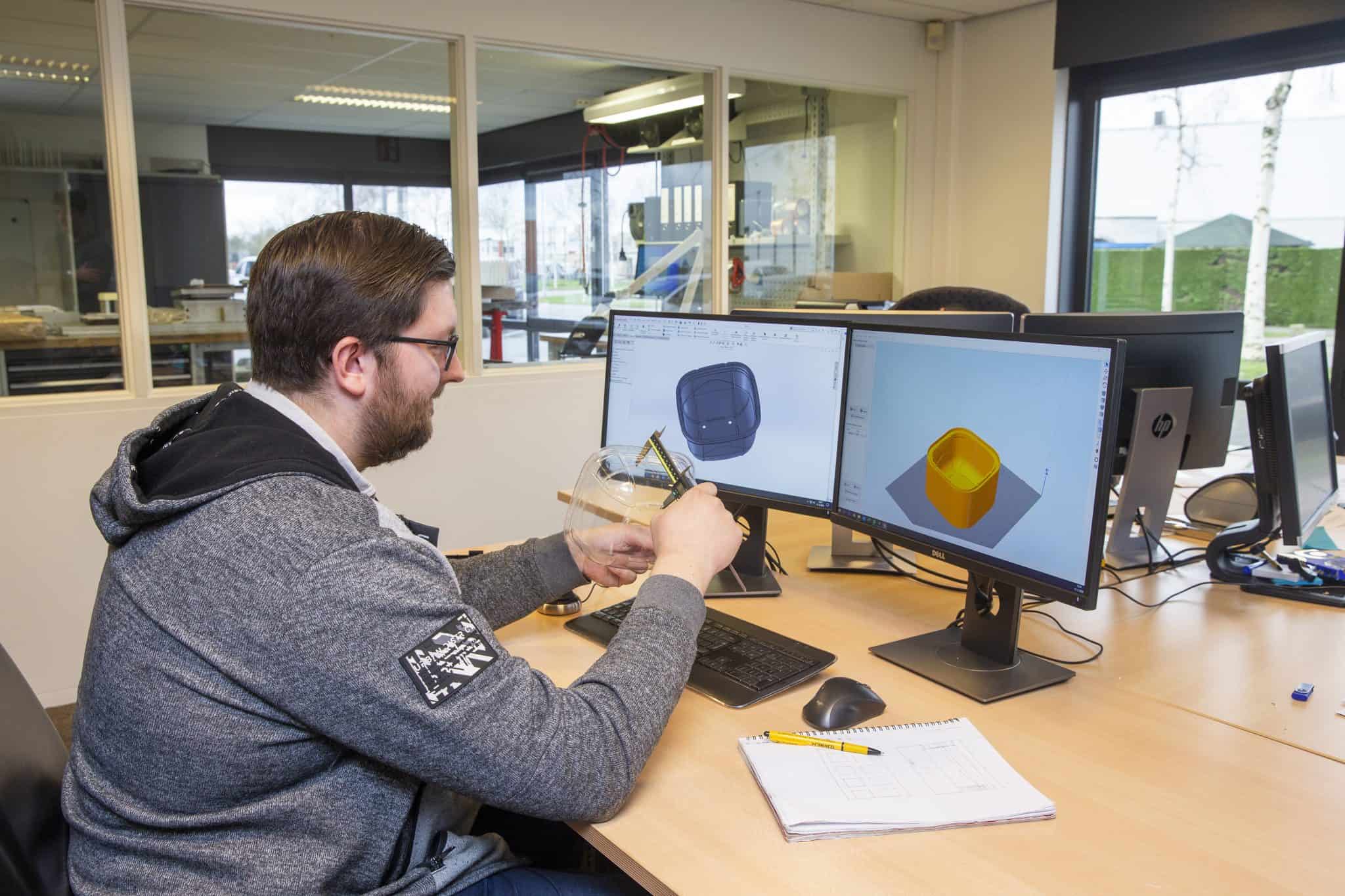

Create your packaging: simply, quickly and together

Welcome to our product configurator. This tool helps you easily put together the specifications of your ideal packaging. Don’t have time to fill everything in, or would you rather have a personal consultation right away? No problem! As a family business, we understand the importance of direct contact. By filling out the configurator, we can be well prepared to start the conversation together and work together on the perfect solution.

Product Configurator

Our product configurator guides you step by step to identify your needs and requirements. Choose the type of packaging, determine the dimensions, and indicate specific details such as material or design. Within minutes, you’ll have a clear overview of your unique packaging requirements, which serves as the basis for our collaboration. It’s simple and quick, just the way we like it.